Assembly.jpg |  Solar Tracker_Base_Rev.JPG |  Mid Base.jpg |

|---|---|---|

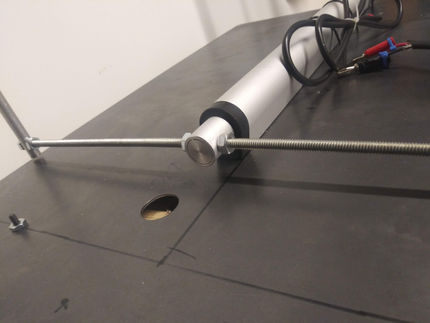

T-Platform.JPG |  Central Support Shaft_Rev.JPG |  Connetor Rods.JPG |

Aluminum Dowel.jpg |

CONSTRUCTION

Methods and Progress

The construction of the device, both mechanical and electrical systems, consist of 15 major components, this is not including variable materials such as wires, bolts, and so on. Of those 15 components, 8 are planned for manufacturing. The other 7 components will be purchased through various suppliers.

The construction of the project is anticipated to be complete on schedule. Electrical implementation and testing for the moving components will commence Spring 2019. Development of the electrical systems has been monitored with an EET assistant (Denis Valsenko) and EET faculty. The steps leading to full completion is continuing:

Manufacture Motor Bearing

Assembly Moving components

Assemble Base

Electrical Implementation

The largest issues addressed at this moment are mainly in logistics. There have been many drawbacks for time management, in regard to adjustments from the initial plan's milestones.

To mitigate these issues, more time has been allocated to making proper adjustments to the design, as well as contacting multiple colleagues and educators for advisement and resource acquisition.

Latest Progress:

Each new acquisition or manufacturing operation, leads to new developments and modifications of other components. For instance, the particular cuts made on the PV frame required new calculations of the mounting points for the links. Also, with the actual diameter of the actuator bearing require resizing of the links; and so on and so forth.

In response to this development, proper measurements and analysis have been undergone multiple times prior to purchasing new parts or starting new manufacturing operations, in an effort to mitigate errors and more analytical work. The project remains on schedule and under budget, with continued help from the MET and EET faculty the project should be a success.

COMPONENTS

Part 1: Wood Platform

Part 2: Central Support Shaft

Part 3: Support Beam/Columns

Part 4: Base Cover

Part 5: 12V DC Battery

Part 6: Microcontroller

Part 7: Arduino Uno

Part 8: Stepper Motor

Part 9: “Lazy Susan” Bearing

Part 10: T-Platform

Part 11: Mount Bearing

Part 12: 3 Connector Links

Part 13: Linear Actuator

Part 14: Panel Frame

Part 15: Sensor Housing

Please view the materials, manufacturing process, and progress of the dual-axis solar tracker below.

Dowel Cuts

Mount Drilling

Frame Mfg.

Clearance Mfg.

Assembly